F1 & MOTORSPORT

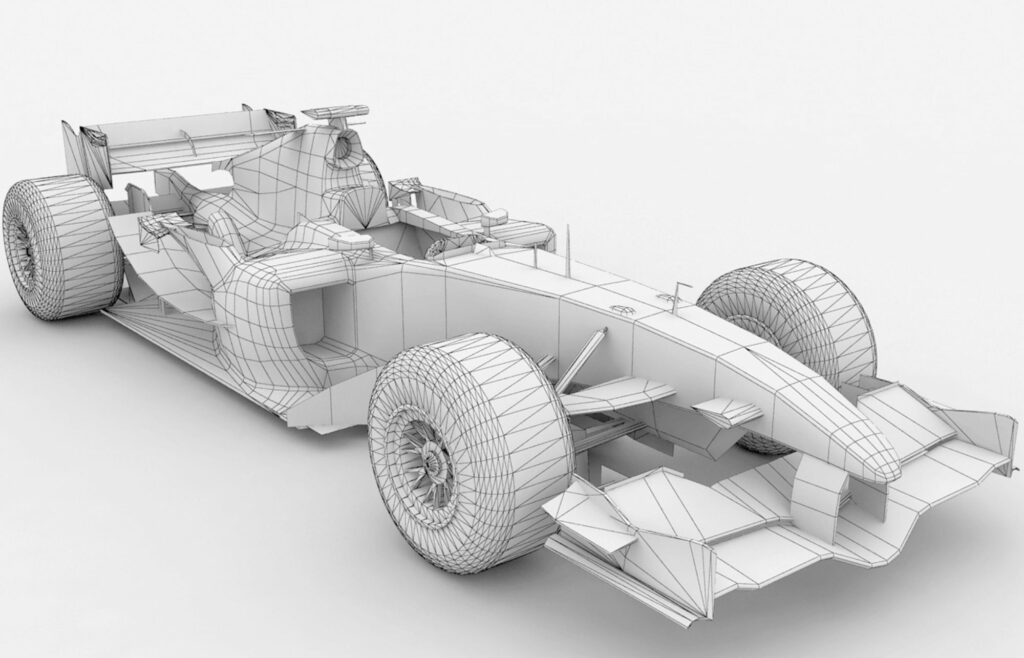

CNC machining plays a crucial role in the world of Formula 1 and motorsport when it comes to reducing both time and cost in producing test pieces. CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computer-controlled machines to precisely shape and cut various materials.

In motorsport, including Formula 1, the development of new parts and components is constant. These parts need to be tested thoroughly before being implemented in the race cars. CNC machining allows teams to quickly create prototypes and test pieces with high accuracy and repeatability.

By using CNC machines, teams can rapidly produce complex components from a wide range of materials such as aluminium, carbon fibre, or various alloys. This process eliminates the need for traditional manual machining methods, which can be time-consuming and less precise. CNC machining also enables teams to optimize the design of parts, reducing weight and improving overall performance.

Additionally, CNC machining helps minimise costs in several ways. First, the automation and precision of CNC machines reduce the likelihood of errors, reducing material waste. Second, the ability to quickly produce test pieces allows teams to iterate designs more rapidly, avoiding expensive mistakes in the final production stages. Finally, CNC machines offer efficient use of materials by optimising the cutting paths, maximising material utilisation and minimising waste.

TMS works with the best names and teams who are at the pinnacle of success in the motorsport arena. We are delighted to be trusted by many of the world’s top Formula One teams. Commercial sensitivity, confidentiality, discretion and our non-disclosure agreements mean that we are limited in the information we can share about our work in this sector, but we are very proud of our valued contribution.

In just a short period of time, Total Machining Solutions Ltd is working with six of the Formula One teams, and we are also the preferred pattern supplier for three of these. As well as our work in F1, we also undertake a lot of work in many other Motorsport arenas.

TMS offers a dynamic CNC machining service which produces the following to the highest precision and very tight deadlines:

- Full size / wind Tunnel models

- Composite Tooling

- Patterns

- Moulds

- Jigs and fixtures

- Bonding Fixtures

- Headrest foams

Aside from our work in Formula one, we also undertake a lot of work in the Motorsport arena. From patterns and moulds to head rest foams.

Automotive Industry

Alongside our involvement with the racing world, we do a lot of work for the wider engineering sectors. This includes:

- Show car models

- Environmental cubes

- Prototype injection mould tools

- Hammer form tools

- Data prove out models

- Environmental cubes

- Mock-ups

- Prototypes

- Checking fixtures

- Aluminium machining

- Cabin interior / exterior mock-ups

- Fully working seat mock-ups

- Environment mock-ups

For more information on how we can help you in your next big project, please contact us today